CATEGORIES

- Motor machinery for Stator

- Motor machinery for Armature

- Motor machinery for Rotor

- Motor parts

- Heat treatment varnish Oven

- Induction cooker machinery

Latest news

- Motor Manufacturers Clinet visit in th

- Motor Testing equipment in Shanghai Ch

- Motor efficiency improvement is an imp

- Hybrid electric vehicle Hairpins New e

- How to produce a big 12KGS Bruless Mot

- Power Coating For Motor Insulation Ele

Contact us

- ADD: No.4 Building , No.1500, Kongjiang Road,Yangpu District,200093,Shanghai,China Skype: motor.machinery

- TEL: 86-21-58992293

- FAX: 86-21-58992292

- E-mail: sales@motor-machinery.com

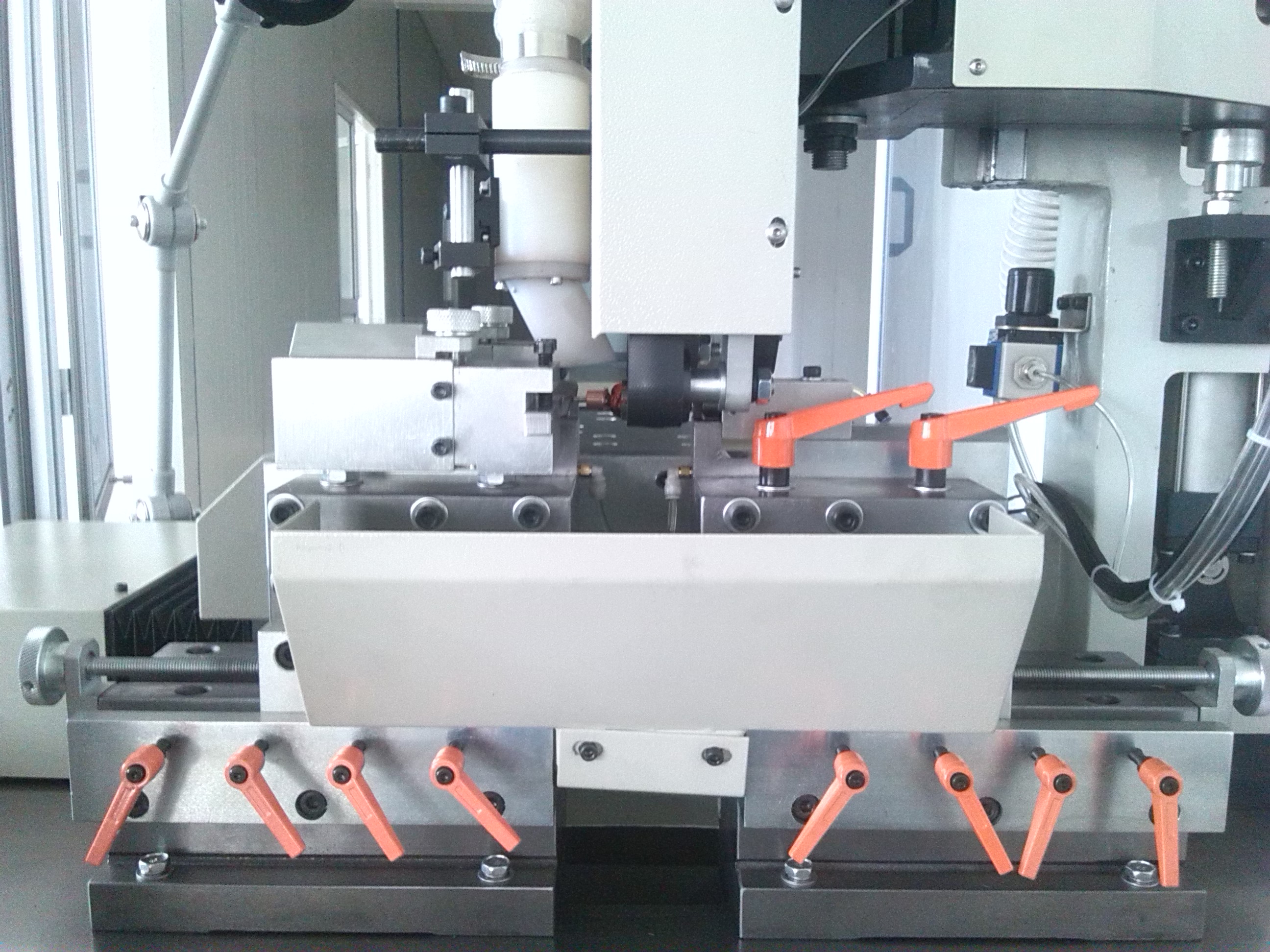

Commutator surface turning lathe WIND-3A-PL

- Servo system

- Precise lathe Turning

- Product description: Turning and milling the surface of commutator to let it polish and shining, commutator turning and burr remover can help the commutator work well with carbon brush.

PRODUCT INTRODUCTION

Armature commutator turning machine precise lathe grind commutator with three axis and servo system WIND-3A-PL, face turning with burr remover and copper remaining industrial vacuum cleaner

How many axis in turning machine?

Three axis turning with three servo system

The smallest armature handled

Lamination OD 22.7mm(0.89inch), shaft diameter 3.0mm Commutator OD 7.0mm

Lathe cutter piece

One piece or two pieces options

Commutator turning process Video:

Lathe commutator (on youtube)

burr remover can help the commutator work well with carbon brush.

Parameter data:

Commutator roundness: ≤0.005mm

(depends on user’s commutator material, armature shaft quality and bearing position quality)

Roughness: ≤Ra 0.4(depends on customer’s armature quality)

Armature OD: Ф20~Ф82mm

Shaft length: 32~250mm

Shaft OD: Ф3~Ф16mm

Commutator OD: Ф8~Ф40mm

Max. cutting volume: first cut—rough cutting Max 0.15mm(in diameter direction of commutator)

Speed regulation range: 0~60Hz

Z direction cutter feeding speed: settable on touch screen, stepless adjustable

Z direction cutter returning speed: set on program

X direction cutter feeding speed: settable on touch screen, stepless adjustable

X direction cutter returning speed: set on program

Z direction cutting length: settable on touch screen, Max. could set 4times different cutting length

(Max 30mm)

Z direction travelling: Max 50mm

Production efficiency: whole cycle≤12sec/pc(twice cutting)

Air pressure: 4~6kg/cm2

Fixture: diamond V shape journal

Total power: 2.2KW

Machine power: 50/60Hz AC230V±10%(single phase)

Burring removing machine power: 50/60Hz AC230V±10%(single phase)

Vacuum cleaner power: 50/60Hz AC380V±10%(three phase)

Weight: about 1,100Kg

Machine dimension: 1,100mm x 1100 mm x 1,830mm3

HS Code:84581100

The lathe turning machine is designed to finish turn the commutator brush track area of

relatively small fractional horsepower motor armatures, starter armatures commutator,

Turning of the commutator brush track area is accomplished through the use of a diamond-tipped tool

mounted onto a precision machine slide driven by a Japanese famous brand Omron A.C. servo motor ,

Turning and milling the surface of commutator to let it polish and shining,

Well and High Quality Control ,

Prompt Delivery ,

New Product ,

Competitive Prices ,

Earth-friendly Products ,

Small Order Acceptable ,

OEM Accepted

Contact: emily@motor-machinery.com

Skype: motor.machinery

Mobile: +86-18067425780

Website: http://www.motor-machinery.com; http://www.coilswinding.com

Pearl

Pearl Emily

Emily